PCBs are available in a four-pack for $60 including shipping in the US.

Email me to order: mroztronium@gmail.com

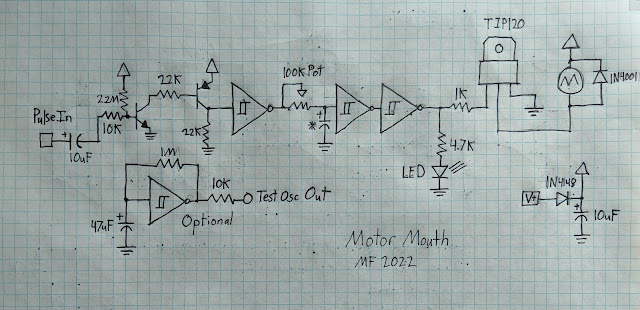

Motor Mouth is a "physical computer" that spins a small DC motor in response to pulses, audio signals, piezos, control voltages or touch. No coding or microcontroller required! It also features a tunable parameter that determines how sluggishly the motor responds to changing input signals.

Motor Mouth is more about interactivity and articulating patterns than motor drivers based around PWM that only let you alter rotation speed. It also is sensitive and compatible with a wide variety of input signals.

Some Applications:

- Simple electro-acoustic expansion for your synthesizers or sequencers

- Connect a piezo to the pulse input and place it near the motor for auto-erotic electro-acoustic feedback shenanigans

- Again with a piezo as input, create a kinetic sculpture that is triggered when viewers step on or touch a surface. A rubber mat or mouse pad in between is a good idea so you don't crack the piezo crystal.

- Control a motor that spins mirrors, translucent materials or other things you can imagine to interfere with video feedback systems

- Build 400 Motor Mouths and rip off Zimoun

There's also an optional test oscillator on the board for compact standalone autonomous operation. Use a photocell instead of the 1M resistor and you have a motor that will spin frequently in lit environments and occasionally in the dark.

Tuning Notes:

The (*) capacitor and the potentiometer determine how sluggishly the motor responds to a changing input signal. A 0.1uF capacitor will respond attentively. A 10uF capacitor will have a decent range of behavior. A 100uF capacitor will take a while to respond to changes. It can be interesting to tune a few Motor Mouths differently and see how they respond to the same input signal. If you build a Motor Mouth or two into an enclosure, you can add a switch to add caps in parallel for multiple flavors.

Powering Motor Drivers:

Motor Mouth can be powered by 5-12V DC. Check your motor specifications.

It's a good idea to use a separate power supply or battery for motor controller circuits to prevent bleed into the audio path (if you care about this). You can gang up a few Motor Mouth PCBs from a single 9V DC wallwart, but using a separate power supply for audio stuff will keep things sounding cleaner.

Small goof-up on first run of boards:

The TIP120 power transistor's legs may be a little too big to fit through the copper-plated holes in the first run of PCBs. Not a big deal. Just trim all three legs about 1/4" and add a bit of solder to one hole at a time as you solder the transistor in place. The flat metal back of the TIP120 lines up with the flat line on the silkscreen. If you mounted it correctly, it should look like this:

Bill of Materials:

(1) Small 6-12V DC Motor - look for "hobby motor" or "toy motor", not "servo motor" or "AC motor"

(1) CD40106 Hex Schmitt Trigger

(1) TIP120 Power Transistor

(1) 2N3904 NPN Transistor

(1) 2N3906 PNP Transistor

(1) 1N4148 or 1N914 Diode

(1) 1N4001 Diode

(1) 1K resistor

(1) 4.7K resistor

(2) 10K resistors

(2) 22K resistors

(1) 1M resistor

(1) 2.2M resistor

(1) 100K linear potentiometer

(2) 10uF electrolytic capacitor

(1) 47uF electrolytic capacitor

(1) 0.1uF-100uF ceramic, film or electrolytic capacitor - bigger cap equals more sluggish motor response

No comments:

Post a Comment